Nanotech marine coatings are revolutionizing the sector, from shipyards to charter and transport companies. Among the most advanced solutions are nanodiamond and CNT (carbon nanotube) coatings, which raise the protection standards of all boat surfaces and drastically reduce routine maintenance.

But what does it really mean to integrate these coatings into standard workflows? And, most importantly, why should marine professionals adopt them?

Why Marine Companies Should Adopt Nanotech Coatings

The main benefits are clear:

How to Apply Nanotech Coatings on Boats

Surface preparation

Surfaces must be clean and free of impurities. SEALS protective treatments ensure maximum adhesion and performance of the nanocoating.

Industrial application

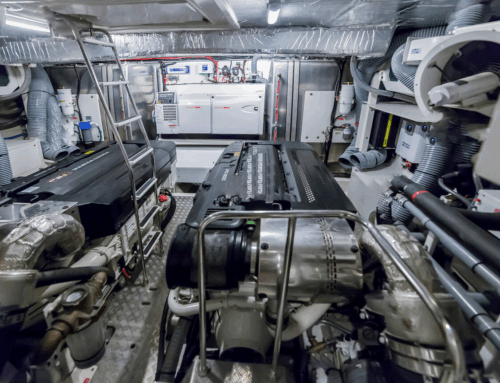

The protective film is applied with a low-pressure airbrush, ensuring uniform coverage and precision even in corners or complex internal areas. Drying times are short (just 2 hours to be water-ready), making integration into existing workflows fast and efficient.

Immediate benefits

Uniform results reduce waste, corrective interventions, and downtime. Shipyards and crews can integrate nanocoatings seamlessly into routine processes.

Marine Maintenance Costs Reduced with Nanotech Coatings

Routine maintenance vs nanocoating

Treated surfaces require fewer interventions. Dirt, salt, and organisms detach easily without damaging the protective layer, making operations faster and more efficient.

Reduced downtime

Fewer haul-outs and restoration works → lower costs and higher availability of the boat. The nanocoating actively protects surfaces while operations continue.

Onboard Maintenance: Daily Benefits for Crews

Simple cleaning and quick checks

A visual inspection is enough to identify micro-scratches or wear. Daily tasks become streamlined, allowing crews to focus on more important operations.

Practical benefits

Luxury Finish and Perceived Quality

Nanodiamond and CNT-based marine coatings give surfaces a smooth, glossy, and high-quality finish. This not only improves durability but also communicates luxury, attention to detail, and professionalism to charter clients and yacht owners.

Conclusion

Integrating SEALS nanotech protective treatments across all boat surfaces is not complicated, but it delivers tangible benefits in efficiency, durability, luxury finish, and cost savings.

SEALS offers personalized consultations to demonstrate the products in action and support seamless implementation in shipyards and onboard vessels.