Marine innovation inspired by space

SEALS was created from the intersection of nanotechnology, aerospace-derived materials and a clear mission: to bring advanced marine protection and the most innovative boat coatings to the maritime sector.

The result is a unique product: durable, flexible, transparent, and eco-friendly

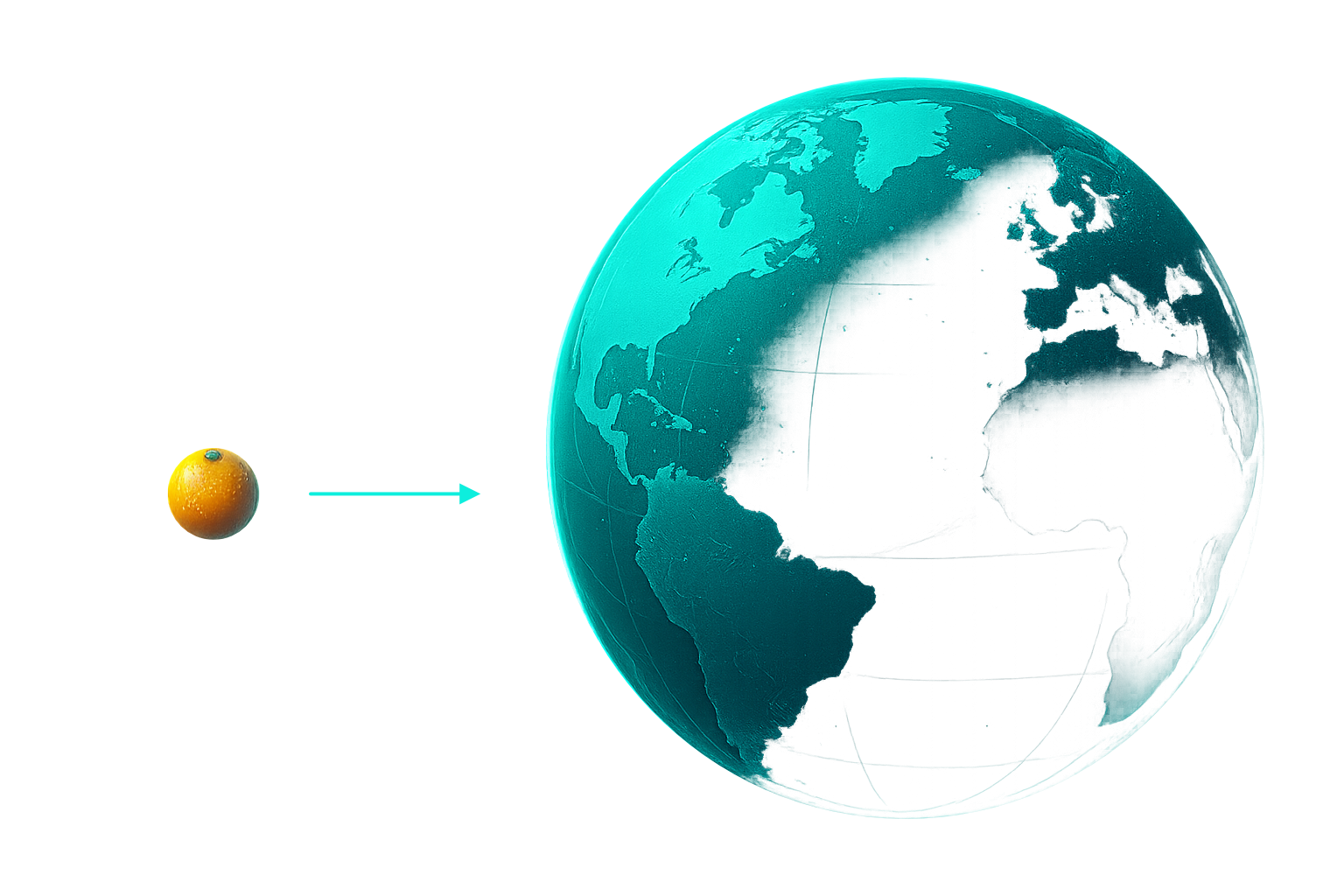

What is nanotechnology?

A nanometer is a unit of measurement in nanotechnology; it is as small as one billionth of a meter, To put that in perspective, if an orange were scaled up to the size of the Earth, a nanometer would be about the size of the original orange. At this microscopic scale, materials acquire extraordinary properties: extreme strength, water repellency, and chemical stability.

KEY MATERIALS

The combination of these elements creates an elastic, ultra-durable, anti-corrosion, water and oil-repellent protective film.

NANODIAMONDS

Invisible Protection, Visible Shine

Enriched nanodiamonds fill the micropores of boat surfaces, creating a continuous, smooth barrier.

Thanks to them SEALS:

PHPS

The Strongest Invisible Polymer

PHPS is the hardest among transparent silicon-based polymers and naturally cures at room temperature.

This innovative material provides:

Thanks to PHPS, SEALS coatings maintain their transparency and strength over time, offering a thin yet impenetrable protection for boats.

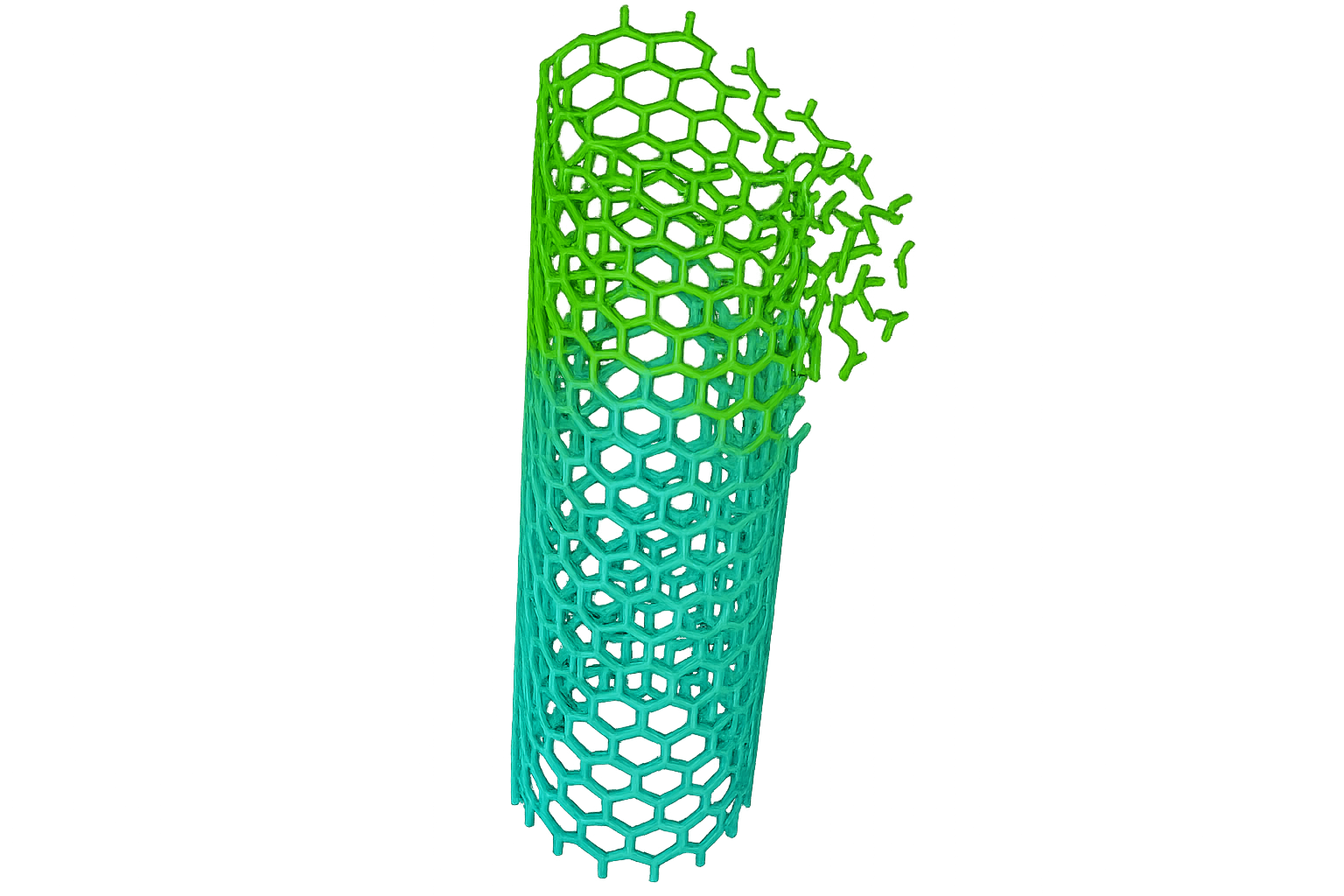

CARBON NANOTUBES (CNTs)

Extreme Flexibility, Uncompromised Strength

Carbon nanotubes are cylindrical nanostructures, ten times stronger than steel yet extremely lightweight.

Integrated into SEALS coatings, they:

The result is a coating that combines hardness and resilience, capable of protecting surfaces even in the harshest marine and freshwater environments.

CERTIFIED PERFORMANCE

SEALS coatings have been tested and certified by SGS, a global leader in quality verification. They have passed the following tests:

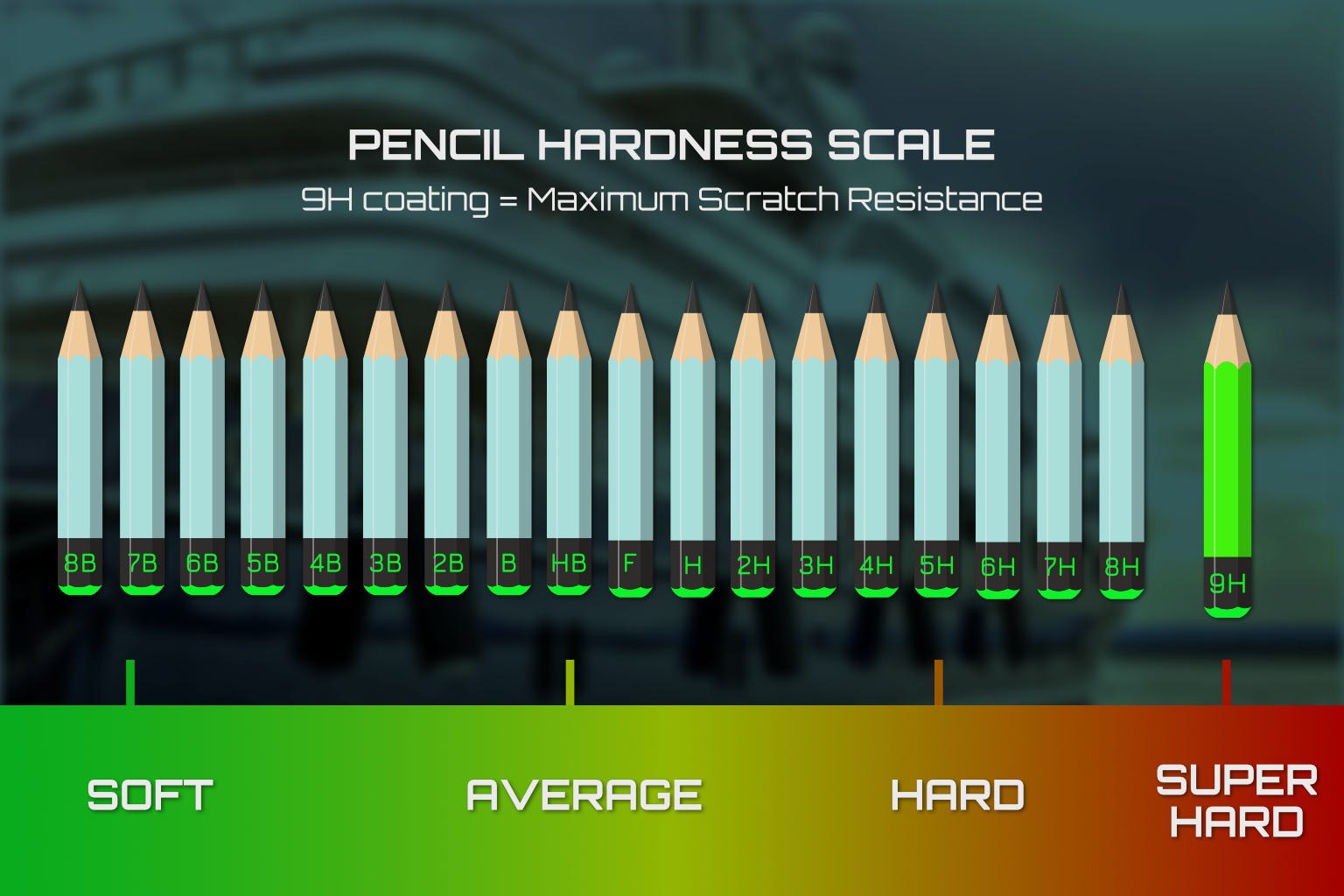

Pencil Hardness – ASTM D3363: maximum hardness (9H on 9H)

The Pencil Hardness test (ASTM D3363) evaluates a coating’s resistance to scratches by pressing pencils of increasing hardness against the surface. Our coatings achieved the maximum 9H rating, leaving no visible marks even under the hardest pencil. This matters because it proves the coating can withstand daily wear and mechanical stress, keeping boats and surfaces protected, smooth, and looking like new .

Chemical Resistance Test – Acid & Alkali Spot Test (ISO 2812-1, modified): Our coating demonstrates excellent resistance to both acidic and alkaline substances, maintaining its integrity and appearance even when exposed to harsh chemical spots.